- Home

- Glass Wool

- Roll

- Glass Wool

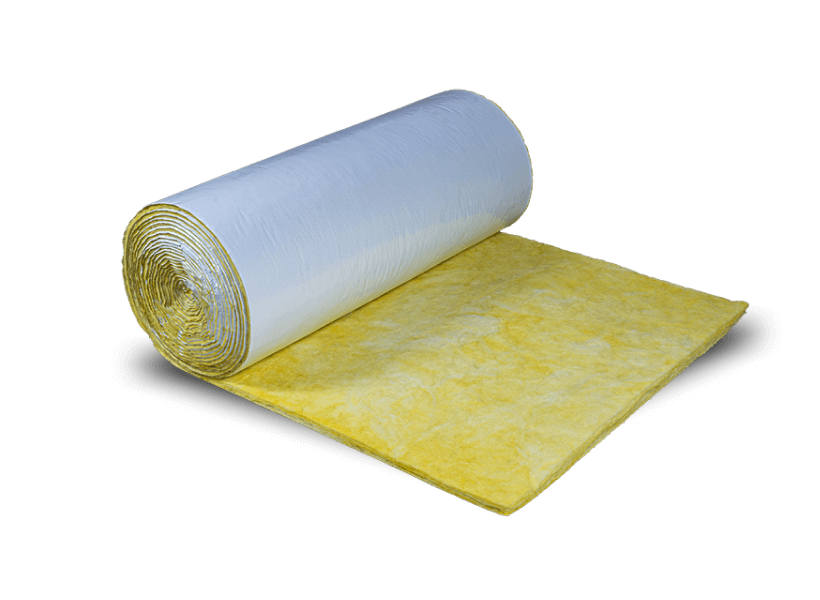

Glass Wool Roll

-

Long resilient blankets

-

Yellow in

colour -

Lightweight and flexible

-

Customized

products -

Fewer joints and less wastage

Range

- Density : 10 to 48 kg/m3

- Thickness : 25 to 130 mm

- Width : 1.1 to 1.2 m

- Length : 7.5 to 30 m

- Available with or without facing

Facings

- Aluminium : FSK, R3035HD, Aluglass

- Polypropylene : White Metalized Polypropylene

- Tissue : FGT, BGT

Basic Information

| Make / Brand | Twigainsul |

| Material | Resin bonded glass wool |

| Standard / Code | IS 8183 |

Product Performing Criteria

| Parameter | Values | Standards |

|---|---|---|

| Thermal Conductivity (W/m.K) | 0.030 to 0.041 at 25oC mean temperature | IS 8183, IS 3346 |

| Thermal Resistance at Specific Thickness (m2 K/W) |

For 25 mm: 0.6 to 0.8 m2 K/W For 50 mm: 1.2 to 1.6 m2 K/W Calculated as per thickness and thermal conductivity of insulation |

|

| NRC | 0.65 to 0.95 | ASTM C-423 / ISO 354 |

General Material Properties

| Parameter | Values | Standards |

|---|---|---|

| Non-combustibility | Non-combustible / Incombustible, Reaction to Fire 'A1' | BS 476 Part 4, IS 8183 EN 13501 |

| Surface spread of flame | NIL, Class 1 | BS 476 part 7 |

| Fire propagation | Class 0, index l <12, sub-index i1 <6 | BS 476 part 6 and 7 |

| Moisture content | Less than 2% | IS 3144, IS 8183 |

| Shot content | NIL | IS 3144, IS 8183 |

| Sulphur / Chloride | Negligible | IS 3144, IS 8183 |

| Mold growth | None | IS 3144, IS 8183 |

| Alkalinity | pH 7 to 10 | IS 8183 |

Certifications and Approvals

| Environment | Fire | Health Safety | Standards Compliance |

|---|---|---|---|

|

|

|

|

|

|||

|

Frequently Asked Questions

Glass wool roll insulation is used for thermal and acoustic insulation in roofs, ceilings, walls, HVAC ducts, and industrial systems such as cryogenic tanks

It reduces heat movement (heat loss and heat gain), helping maintain stable temperatures and lower energy consumption.

Commercial construction, HVAC, manufacturing, infrastructure, transportation, and OEM sectors widely use it.

Yes, glass wool roll insulation is non-combustible and meets key fire safety standards such as BS 476 part 4, 5, 6 &7.

High-quality glass wool rolls offer low thermal conductivity, ensuring effective thermal resistance (R-value). This (R-value) depends on the installed thickness and thermal conductivity of the product.

Its micro-air pockets within the fibrous structure virtually resist the airflow thus absorbs sound, reducing noise transmission and improving indoor acoustics.

Glass wool rolls are available in multiple densities (12- 48 Kg/m3) and thicknesses (25-130 mm) to suit different performance needs.

Selection depends on thermal targets, acoustic requirements, fire ratings, and application type.

Glass wool rolls are lighter and easier to install, while rock wool typically offers higher density and impact resistance.

Yes, it is widely used for HVAC duct insulation and acoustic wrapping.

Glass wool roll is suitable for moderate-temperature applications; higher-temperature systems may require specialized insulation.

Why Glass Wool Roll Is a Preferred Insulation Solution

Glass wool roll insulation is one of the most commonly used multipurpose insulation materials in commercial buildings, industrial facilities, and HVAC systems. It is valued for its good thermal insulation, effective sound control, and fire-safe performance, making it suitable for a wide range of applications. Moreover, the material takes less space for transport and storage when compared with board/ slab products of similar properties.

Glass wool insulation meets established industry and test standards such as IS 8183, ASTM/ISO and recognized fire safety classifications e.g FM, Class 0/ Class 1. Certifications like EUCEB and acceptance under green building guidelines give assurance on quality and consistency. Glass wool rolls are reliable, easily available, generates less waste during installation, and provide long term solution. It ensures stable insulation performance throughout the project lifecycle.

Thermal Performance Delivered by Glass Wool Roll

Glass wool roll insulation is engineered to minimise heat transfer through roofs, ceilings, walls, and mechanical systems. Its low thermal conductivity enables effective control of heat loss and heat gain, contributing directly to reduced energy consumption and stable indoor temperatures. Performance can be precisely matched to project needs through a wide range of thicknesses and densities. Thicker rolls provide higher thermal resistance, while optimised densities ensure consistent insulation performance without excessive material usage. These characteristics make thermal insulation glass wool roll solutions ideal for roofs, suspended ceilings, under-deck insulation, and HVAC systems where energy efficiency and performance assurance are critical.

High-Performance Specifications That Matter

Glass wool roll insulation is available across multiple technical configurations to meet project-specific requirements:

- Density, typically ranges from 12-48 Kg/m3 and thickness ranges (25 – 130 mm) designed for varied thermal and acoustic demands.

- High thermal resistance that helps to comply prescriptive requirement of Energy Conservation Building Code (2017), or ASHRAE 90.1

- Superior sound absorption performance (NRC > 0.75 ) that helps to design acoustic sensitive spaces

- Supplied in roll formats with or without facings such as aluminium foil, polypropylene, aluglass, etc.

Customized and well-designed glass wool rolls allow architects, MEP consultants, and facility managers to align insulation specifications with fire safety norms, condensation control needs, and installation conditions. This flexibility ensures compliance without over-engineering, supporting efficient design and procurement decisions.

Multi-Sector Application Intelligence

Glass wool roll insulation delivers clear value across multiple sectors:

- Building & Infrastructure: Roofs, ceilings, cavity walls, and under-decks for thermal and acoustic comfort

- HVAC Systems: Duct insulation and acoustic wraps to control heat loss and reduce operational noise

- Industrial & OEM: Equipment insulation, process systems, and areas requiring temperature control

- Specialty & Mobility: Bus bodies, rail components, and transportation insulation applications

The right insulation choice directly affects energy efficiency, operating costs, and equipment reliability, making glass wool insulation a dependable solution rather than a basic commodity material.

Sustainability as a Strategic Business Driver

Glass wool roll insulation supports sustainable construction and corporate ESG goals through energy conservation and responsible material use. By reducing heating and cooling loads, it contributes to lower operational carbon emissions and improved building efficiency.

Glass wool products typically contain high recycled content and support compliance with green building frameworks such as GRIHA, IGBC, and LEED, making them a strategic choice for sustainability-focused developments.

Why Glass Wool Roll Fits Modern Project Requirements

Glass wool roll insulation meets the demands of modern commercial buildings, industrial facilities, HVAC systems, and large infrastructure projects through consistent performance, regulatory compliance, and installation efficiency. Its balance of thermal efficiency, acoustic comfort, and fire safety reinforces confidence among decision-makers seeking predictable, long-term insulation performance.